Prototype One set the tone for our production vehicle. Here are six defining traits.

A visceral powertrain

At the center of the LM Coupe prototype sits the lightest, most responsive and highest revving inline 6-cylinder engine ever made. Rigidly mounted to the chassis, it transmits a symphony of sounds and vibrations that are pure motorsport in nature. The LM Coupe delivers a driving experience that triggers your most primal instincts. The incredible powerplant is complimented by a six-speed manually operated sequential transmission. The engine and gearbox weigh a combined 225 pounds (102kg) – less than the transmission alone in some competitors’ cars.

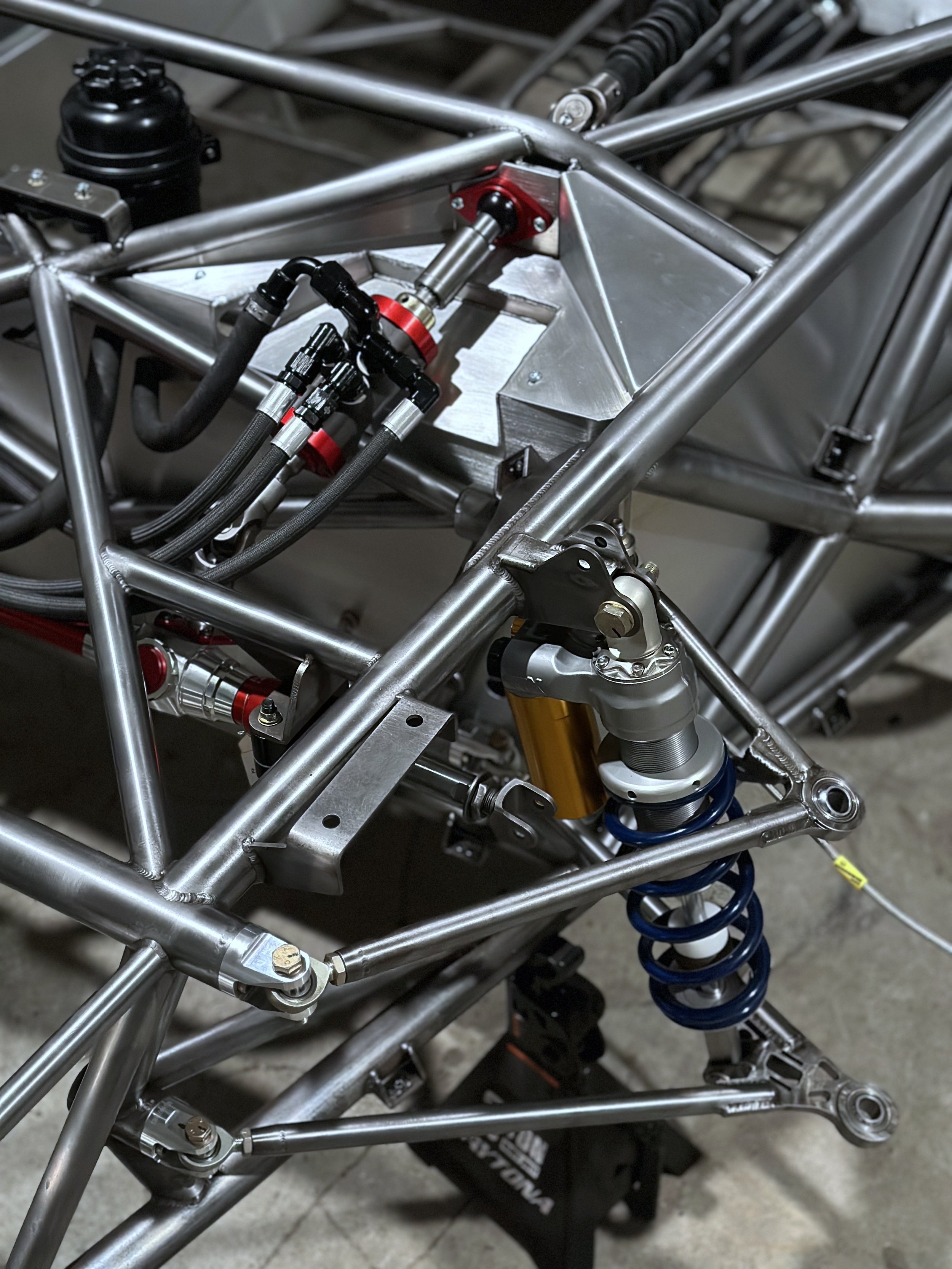

Suspension developed by F1 engineers

Our prototype’s kinematic design started with outrageously adjustable double wishbone geometry developed in collaboration with Formula 1 engineers. Our own center-lock wheel design houses mighty AP Racing calipers and rotors, providing impeccable stopping power. Four custom valved Öhlins dampers keep the tires glued to the ground, ensuring a perfect balance of uncompromised driving pleasure and raw performance. A center of gravity among the lowest of any production vehicle allows for soft spring rates while negating body roll. All of the suspension components can be rose-jointed as a result.

Motorsport derived steering system

A driver’s car is nothing without steering that communicates every detail of the road. A motorsport-grade steering system was the only option that could provide the precision the LM Coupe is designed to deliver. The hydraulically assisted rack has its origins in Le Mans Prototype and GT racing series, and it is lighter than a comparable unassisted rack thanks to the force-absorption that the hydraulic servo provides. With a lightning- quick 1.9 turns lock-to-lock, its razor- sharp response fires purely analogue feedback to the palms of your hands.

Race-grade tubular chassis

A racing heart demands equally strong bones to contain its power. The tubular spaceframe is made of latest-generation steel alloy and gives the prototype one of the highest specific stiffnesses of any modern vehicle. Aluminum panels reinforce the lightweight structure and will be replaced by bonded carbon panels for production. They surround occupants in a safety cell up to the standards of the highest echelons of motorsport.

An interior from the starting grid

Occupant comfort and visibility were among the most important factors during the design phase, as was the track-ready mentality with which the interior was laid out. A 3D printed prototype seat positions the driver so their centerline perfectly aligns with the steering wheel and pedal box. The reclined seating position mimics an astronaut’s relaxed body position in zero gravity and imbues a sense of comfort and alertness simultaneously. The metal switchgear, forged pedals, wood-trimmed shifter and leather wrapped steering wheel provide a sense of quality and durability not typically seen in prototypes - a sign of what’s to come.

Production oriented mindset

Our prototype is comprised of several thousand individual components, the majority of which are designed and engineered in-house. Every one of them has a part number, inventory tracking, quality and version control as part of a comprehensive internal database, which was also developed in-house and based on aerospace industry standards. In terms of production-readiness, Shoreline is already operating as a small-scale OEM rather than a boutique automaker. This is unique in the low-volume sector, and it is what allows us to develop collector-grade vehicles that will last generations.