Edition #ELEVEN

On a Roll(ing Chassis)

(This newsletter was previously sent out to our email subscribers. To receive updates the moment they happen, consider subscribing via our home page.)

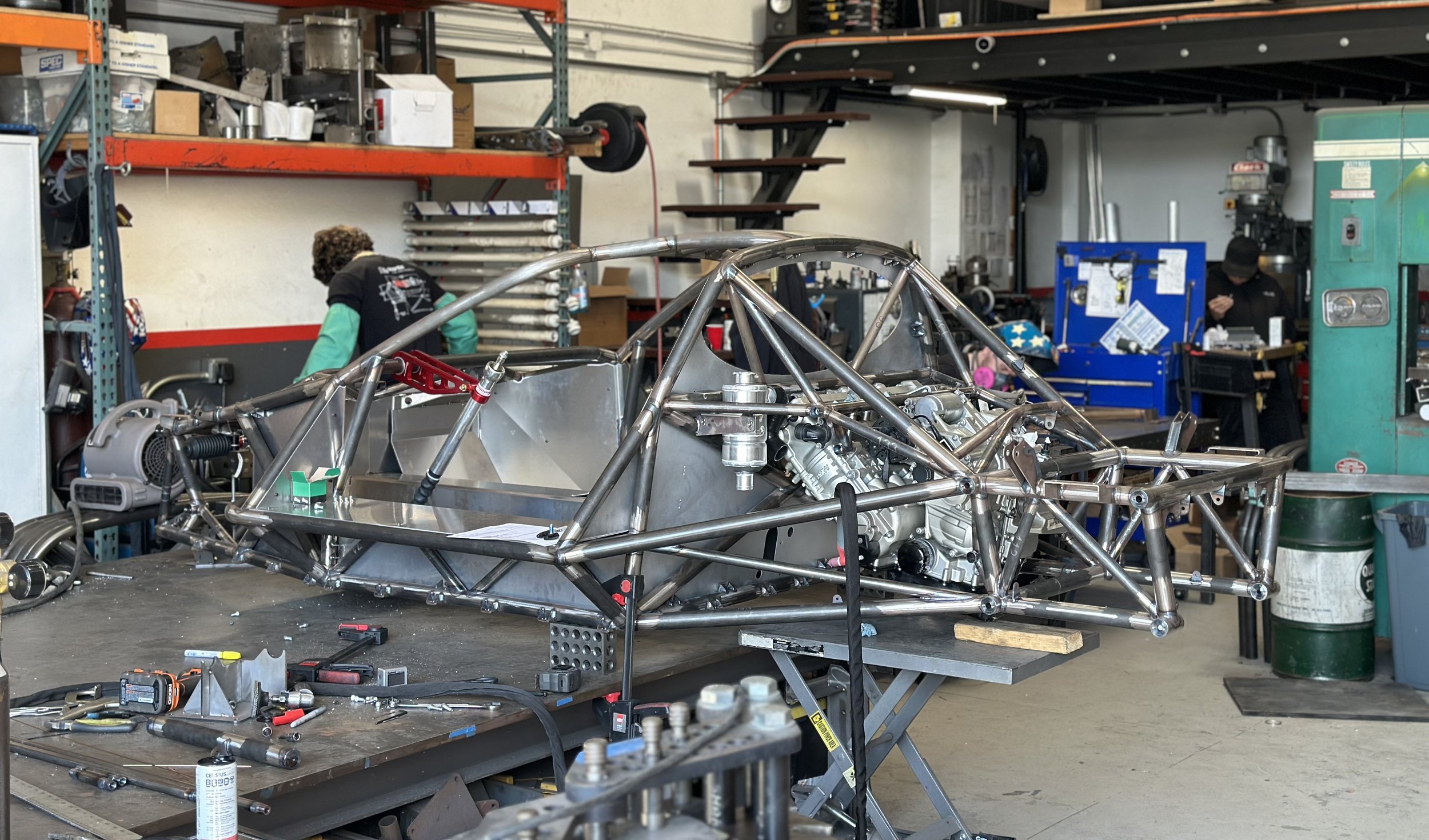

The month of October saw Shoreline Bespoke reach a huge milestone: Laguna Prototype 1 is sitting on its wheels for the first time! The labor-intensive chassis fabrication came to an end in the first week of October, at which point we began final assembly. By mid-October (just in time for my 31st and the best birthday present I could have asked for) the prototype was ready to be wheeled onto a trailer and taken to the garage of some very generous friends who let us “move in” to prepare the prototype for its first on-road tests. Below is a recap of everything leading up to that incredible moment.

The first step was to fit the sheetmetal interior panels that define the passenger compartment. The production car will have molded carbon interior panels, but even the prototype aluminum panels gave us millimeter-perfect panel gaps that would put some production vehicles to shame. This is just one of many examples of the engineering excellence that exudes throughout Shoreline Bespoke’s first ever vehicle.

We began by installing the front bulkhead panels and then worked our way backwards. At this point we also installed Laguna’s bespoke hydraulic steering rack. The red and gold anodized aluminum gave our bare chassis its first splash of color - in person it can only be described as automotive jewelry. If you’re wondering why we made the decision to run power-steering on such a lightweight car, there are a few reasons. Power-steering is actually prevalent in sports car racing, mainly to provide assistance when drivers need it most: during accident avoidance such as high-speed corrections, catching a slide, or swerving around debris on a circuit. A hydraulically- assisted system will also allow us to develop a more consistent and tailored steering feel for Laguna, especially at low speed. Lastly, this motorsport-derived power steering rack is actually lighter than an equivalent unassisted rack because the hydraulic servo absorbs steering forces, meaning the rack itself takes less force and can therefore be made smaller and lighter. The power-steering system adds immense experiential value in its adjustability, refinement, and safety for a near-zero weight gain.

The 12 gallon FIA-certified fuel cell went in next. The decision to use a motorsport-grade tank was fueled (I’ll show myself out) by our commitment to engineering excellence. Laguna uses an advanced returnless fuel system - the engine’s computer provides the exact amount of fuel needed at all times. This way, the return hose (which normally carries excess fuel back to the tank) is eliminated, saving weight. You can also see the black hydraulic pump for the steering system, which is electric instead of belt-driven to further increase efficiency. In the production car, it will also provide hydraulic pressure for the front axle lift system.

For the most part, the interior panels fit together flawlessly. Watching them literally snap into place was so gratifying! Once all of the panels were fitted, we test-fit the seats and then removed them to install my favorite part of the car: the engine. With the seats removed, I was able to stand inside the car and help guide the engine into place. The compact 6-cylinder is light enough that I was able to hold it in place while Kyle bolted it in. Given that my hands were full, I don’t have pictures but it looked similar to what I’m doing in this photo (except more helpful).

At this point we were on a roll, and pleasantly surprised with how fast assembly was moving after such a long wait for the chassis fabrication. We arrived early the next day, determined to finish the suspension so that we could come back the following morning with a U-Haul trailer and take Laguna Prototype 1 to her new home. We installed the suspension for all four corners in less than half a day, and suddenly realized we needed tires! A last minute call to the local shop paid off, and on the lucky-for-us Friday the 13th, we rolled the vehicle out of the shop for the first time. That concluded an intense and challenging three months of fabrication. And now, on to the next chapter: the road to First Start.

For the next several weeks, we will be buried in wiring and plumbing for Laguna’s electrical, cooling, and brake systems. After that, Kyle and I can fire up the engine for the first time. In the meantime, you can poke around here to learn more about our vision for Shoreline Bespoke, reach out, and shop for apparel. By subscribing to this newsletter, you’ll be the first to know about vehicle updates, future reveals, apparel releases and more… stay tuned.

Sincerely,

Spencer Beckman

Founder & CEO, Shoreline Bespoke Vehicles